teachings / y — @ La Scuola Open Source (Bari)

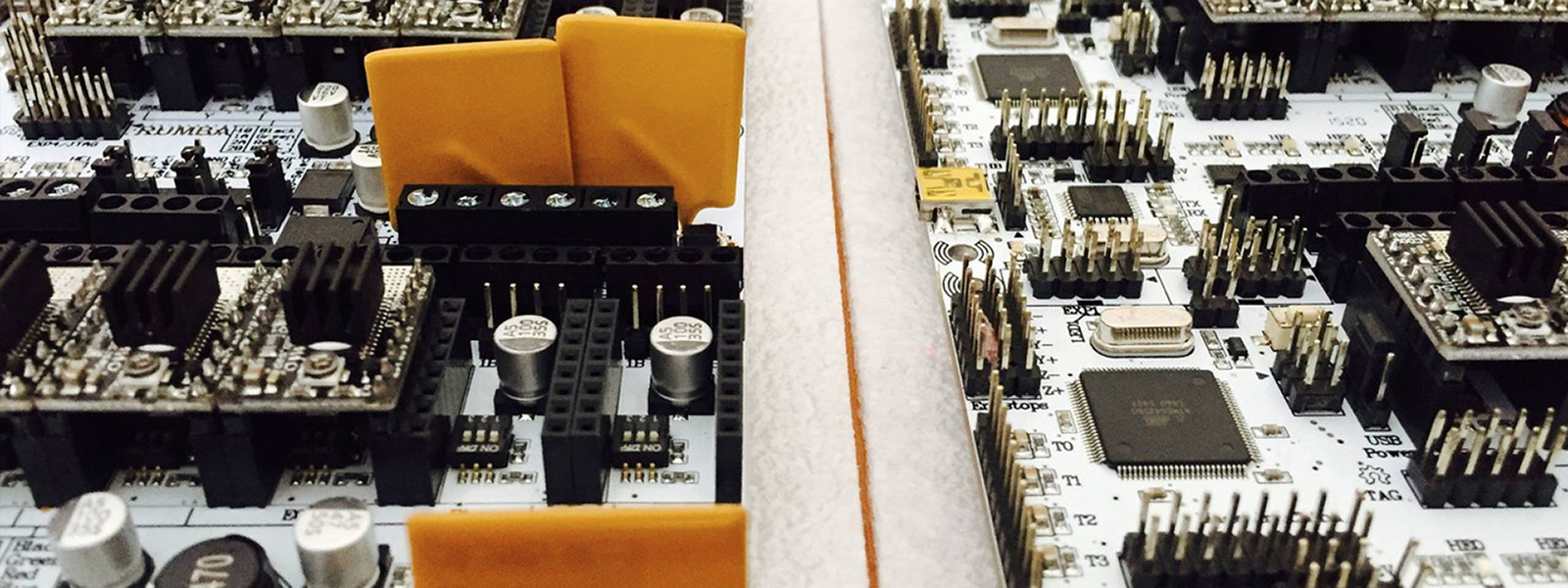

DIY CNC CUTTER

Raffaele Giancipoli — Designer / Maker @ How/Art

Category: Workshop

Level of difficulty: advanced

Topics:

- digital craft

- making

- do it yourself

- tools

Mode: 4 weekly meetings for 4 weeks

It will take place at: La Scuola Open Source (Bari)

Total duration: 32 hours (break not included)

Cost: 150 €

Output: products, skills

Recommended for

students, researchers, professionals, companies, immigrants, unemployed

Min. number of partecipants to start: 20

Max. number of partecipants: 25

Held by:

-

Raffaele Giancipoli

Designer / Maker / How/Art

Raffaele Giancipoli is one of the How/Art partners, an start-up project based on the production and sale of 3d printing hardware, currently aiming to enter the job market as developers and makers of projects connected to open hardware, open source, technological innovation, making, domotics, design and smart set-ups. In june, 2015 How/Art launched its first 3d printing device /QUDA in all the Ipercoop malls of Puglia, Basilicata and Emilia Romagna: for the first time ever, a low cost, open source product with high technological potential is launched in large-scale retail trade environments, aiming to make such technology accessible to as many users as possible.

What is it about?

You will learn how a multi-function cnc cutting machine works building it together with the other participants, after the course the built milling cutter will be kept in the School, with all the course participants being able to use it for free for the following 12 months.

The following skills will be acquired throughout the workshop:

☛ Designing a cnc machine;

☛ How to control cnc machines via PC-installed open source software and printer-installed rotative controllers;

☛ Interpreting and writing GCODE for CNC machines controlling;

☛ How to design a cnc machine;

☛ How to choose and assemble the needed mechanical components required for the cnc machine movement;

☛ Designing and editing 8- and 32-bit firmware needed to manage cnc hardware;

☛ Electronic assembly of a CNC machine by using open source hardware components.

What will we work on?

Will be to realize a CNC machine ready for use, when needed, as Drawing machine, 3d printer, milling and laser-cutting machine. The machine will be entirely and wholly designed and assembled in each of its parts throughout the workshop.

How does it work?

The workshop’s activities will focus on two main objectives:

☛ Provide the needed mechanical, electronical and IT notions required to design CNC hardware;

☛ Build, starting from the acquired notions, CNC hardware able to operate in a completely autonomous way.

Participants will split in three groups according to the needed skills. Groups will deal, respectively, with:

☛ Electronics: Understanding, designing and assembling the electronical components of a CNC machine;

☛ Mechanics and structure: Designing, building it and assembling the structural components of the CNC machine: assembling the mechanical components and testing its motion features together with the “electronics” team;

☛ Firmware: Identifying the most fitting open source board type to control the CNC machine among those provided by How/Art. Firmware programming and testing together with the “electronics” group.

↳ Courses will start once the minimum number of participants is achieved.

By clicking on SUBSCRIBE you’ll get access to a form to be filled in to complete your enrolment request:

If, within the deadline, the maximum number of participants is exceeded: we will select the partecipants, you’ll receive an email with all the informations about the selection and the activity start.

If, within the deadline, the minimum number of participants is reached: you’ll receive an email with the payment details (PayPal or bank transfer). Once you’ve charged it, you’ll receive a receipt confirmation and the details of your course.

This process is designed to assure everyone the utmost transparency and the economic sustainability of the courses.